Calculation to Estimate the Molecular

Weight

of a Petroleum Oil from Two Viscosity

Measurements

That Models ASTM D2502 Chart

INTRODUCTION

The ASTM D2502[1] standard test method uses kinematic

viscosity measurements[2] in

cSt of a petroleum oil at 100 °F (V100, V1) and 210°F (V210, V2) to

estimate its molecular weight. The method requires looking up an “H” function (H100=870*Log(Log(V1+0.6)+154))

from a table based on the viscosity at 100°F. The table H100 function is then

located on the vertical y ordinate axis of a chart. Following that value horizontally

across the chart until it intersects with the line of viscosity V210 for the

oil and then dropping vertically down to the horizontal x abscissa axis, the

molecular weight (MW) can be read for the oil.

PROBLEM

The H100 function value in the ASTM D2502 table, its point

on the chart ordinate, the lines of constant viscosity (isostoke) at 210°F and

the MW on the abscissa may all require interpolate or estimating their

locations. The H100 function and spacing of the lines of V210 isostokes are

inherently nonlinear making their estimation even more problematic. These

issues make the method tedious, time-consuming and prone to error.

The procedure is only valid when using the large chart ASTM

developed for the method. This implies using the small chart supplied with the

method is not appropriate, as “the precision statements given in the method

will not apply”. Obtaining the large chart and the difficulties in handling it

are additional annoyances that distract from getting correct reading.

A method to calculate the molecular weight from the viscosities

would eliminate these errors.

SOLUTION

Calculation

The following original calculation algorithm[3] models

the entire ASTM chart. Lines in this paper with alphabetic character(s) in parentheses,

an alternate typeface and indented lines designate program calculation code. The

code only lists the lines needed for the calculation and not any GW-BASIC

definition statements (DEFINT, DEFSNG,

DIM), line numbers or input and output statements. Comments precede sections of

the calculations to describe their purpose in the computation.

At the end of the paper is the molecular weight calculation

coded in GW-BASIC and in Excel VBA that uses viscosities in cSt at 100°F

and 210°F. Those viscosities are the ones used in the ASTM method. The Excel

VBA has an option to check if the viscosities are valid and within the range of

the chart. Since viscosities at these temperatures is less common, an additional

VBA function is available that will convert viscosities from 40°C and 100°C for

use in the calculation.

Caution, the logarithmic function has inconsistent naming

formats in various programming languages. The same format can reference

different bases for the logarithm. Table 1

has the format and base for GW-Basic, Excel VBA and Excel worksheets. Any code

listings are in the format used by that language so there is minimal editing

when copied.

Table 1 Logarithmic Name Formats in this

Paper and Codes

The calculation lines (a) through (ag) are in GW-BASIC. Throughout

the paper, “H” function uses the Log base 10 while the “F” functions use Ln

base e.

This is the main polynomial fit using generalized H100 and

H210 functions defined as F1 and F2 along with a generalized difference function

of F1 and F2 (F12).

F1=LOG(LOG(V1+C(1))) (a)

F2=LOG(LOG(V2+C(2))) (b)

F12=LOG(F1-C(3)*F2-C(4)) (c)

MW0=C(5)+C(6)*F12+C(7)*F12*F2^2+C(8)*F1^4+C(9)*F1*F2*F12 (d)

MWS (molecular weight scaled) is the scaled primary

molecular weight (MW0) for use in elliptically skewed normal distribution fits

to correct for patterns seen in the residues from (d).

MWS=MW0*0.01 (e)

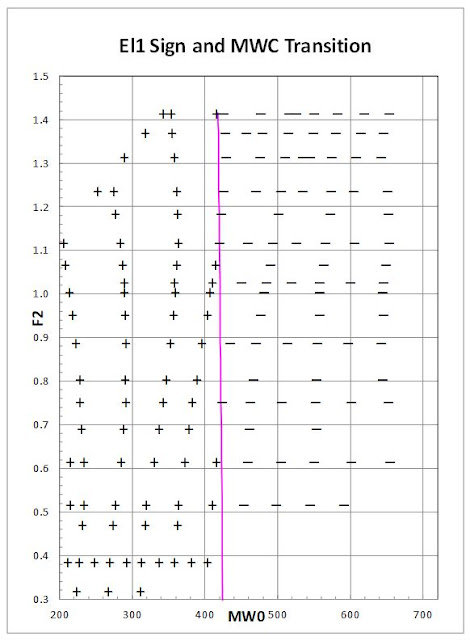

There were 2 areas that had a pattern of residuals from fitting

(d) to the data. One area had negative residuals and the other positive

residuals. Figure

3 is an example of the pattern seen for the Hirschler

model defined by equation [7]. The model (d) has a similar pattern of

residuals. Additional calculations corrected for these patterns. The correction

terms for both areas are elliptically skewed normal distribution fits with axis

rotation and translation. Below is the listing (g) to (s) for the first

correction term used to model the area of negative residuals.

SI1=SIN(C(10)) (g)

CO1=COS(C(10)) (h)

X1=(MWS*CO1+F2*SI1-C(11)*CO1-C(12)*SI1)/C(13) (i)

X12=X1*X1 (j)

Y1=(F2*CO1-C(12)*CO1-MWS*SI1+C(11)*SI1)/C(14) (k)

Y12=Y1*Y1 (l)

EL1=X12+Y12 (m)

SG1=TAN(C(10))*(-C(11)+MWS)+C(12)-F2 (n)

IF SG1<0 THEN SG12=-1 ELSE SG12=1 (o)

EX1=SG12*EL1 (p)

EX11=EX1*(C(19)+EX1*C(20)) (q)

EX12=EX1*(C(17)+EX1*(C(18)+EX11)) (r)

MW1=C(15)*EXP(-(C(16)+EX12)) (s)

Calculation lines (t) to (af) below

is the listing for a second correction term for modeling the area of positive

residuals. It is the same as (g) to (s) but with variable names altered to

define it as the second term.

SI2=SIN(C(21)) (t)

CO2=COS(C(21)) (u)

X2=(MWS*CO2+F2*SI2-C(22)*CO2-C(23)*SI2)/C(24) (v)

X22=X2*X2 (w)

Y2=(F2*CO2-C(23)*CO2-MWS*SI2+C(22)*SI2)/C(25) (x)

Y22=Y2*Y2 (y)

EL2=X22+Y22 (z)

SG2=TAN(C(21))*(-C(22)+MWS)+C(23)-F2 (aa)

IF SG2<0 THEN SG22=-1 ELSE SG22=1 (ab)

EX2=SG22*EL2 (ac)

EX21=EX2*(C(30)+EX2*C(31)) (ad)

EX22=EX2*(C(28)+EX2*(C(29)+EX21)) (ae)

MW2=C(26)*EXP(-(C(27)+EX22)) (af)

The main polynomial molecule

weight, the 2 correction terms and an offset are summed to give the final MWC.

MWC=MW0+MW1+MW2+C(32) (ag)

Definitions

Table 2

is a listing of the coefficients. C1, C2, …C32 are alternate references to

these coefficients used elsewhere in the paper. Table 3

lists major variables and GW-BASIC reserved words used.

Table 3 Listing of Important Variables and

GW-BASIC Reserved Words

RESULTS

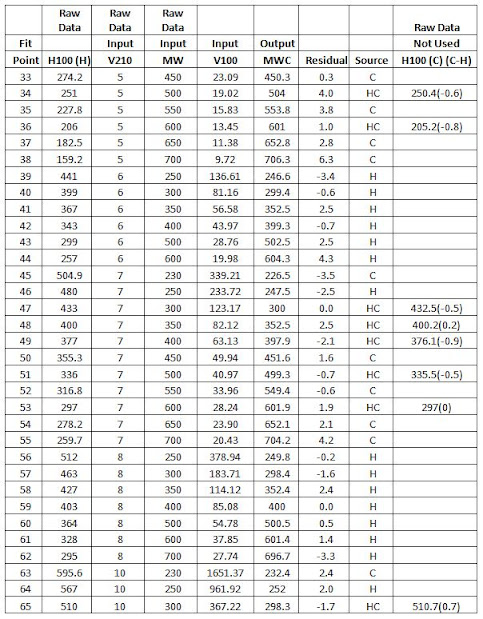

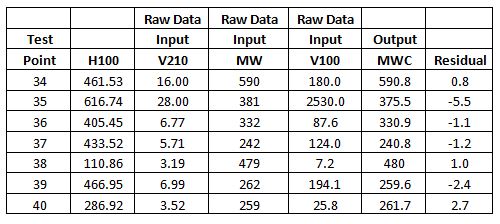

Optimization of the coefficients in the model used one

hundred and sixty two data points for fitting. The raw information for the data

points was H100, V210 and MW. Testing the model used 40 pairs of randomly

generated V100 and V210 values. The H100 value calculated from V100 and the

V210 viscosity allowed finding the MW from the chart. Table 4

has the statistics comparing the MWC’s to the MW’s for the 2 sets of data along

with ASTM precision data.

Table 4 Model Fit to ASTM D2502 and

Validation Statistics

ASTM D2502-92 (Reapproved 1996) has a 3 g/mole repeatability

(r) and a 25 g/mole reproducibility (R) but it was not obtained in accordance

with R:D02-1007, “Manual on Determining Precision Data for ASTM Methods on

Petroleum Products and Lubricants.” Assuming laboratories received pairs of

viscosity values and they determined the molecular weights, the repeatability (r)

and reproducibility (R) can be calculated from the reported MW’s. The

relationship to the standard deviation (SD) for r and R (Sr and SR)

is assumed to be S= (r or R)/(Z*sqrt(2)) with the Z score of 1.96. The model

has about twice the fit error as the repeatability of reading the chart using

duplicate data by a single person in a single laboratory and 1/4 of the

reproducibility error between laboratories. The calculation is much better for

comparisons between laboratories. The initial fit of 110 data points showed

around 15-20 points with large differences between MW and MWC. Rechecking the

data to eliminate any that were outliers caused by inadvertent estimation and

reading errors showed ten were inaccurate. If this is typical, then 10% of

values determined from the chart will be in error.

The conclusion is the model reasonably estimates the values

from the ASTM D2502 chart. The avoidance of inadvertent estimation errors is a

better trade off as the loss in precision is smaller than the potentially larger

errors during the estimation process. As it will be shown later, the loss in

precision is small compared to the actual variation of the experimental data.

DISCUSSION

Data Modeling and Testing

The initial work used 110 data points selected from the

22x28 inch chart offered by ASTM. Comparing these to the one hundred and three

points reported in the original paper by Hirschler[4] (page 158, Table XI) showed fifty-one

of them to be duplicates. Because the H100 had to be estimated, there were

differences in the H100 values between the duplicate sets with the largest

being 4. For the duplicate data, Hirschler’s data took precedence over the data

read from the chart. This gave one hundred and sixty two data points to

determine the coefficients for the model (fifty-nine taken from the 22x28 inch

chart offered by ASTM and one hundred and three from Hirschler).

These additional points were chosen from the chart to

extended the extremes of the H100 function, to extend the extremes of the

molecular weights, to fill in gaps on the original data (450, 550 and 650

molecular weight) and to included points on the 15 cSt at 210 °F isostoke.

This gave a uniform coverage of the chart. The points chosen are where the H100

lines crossed isostokes of the 210 °F viscosities defined on the

chart. This allowed for a more consistent linear interpolation of the axis

values of the molecular weight, as the spacing between the 210 oF isostokes

is non-linear. These points along with 40 additional test points used to

determine the coefficients in the model are in Figure 1

along with their distributions in Figure 2.

Figure 2 Distribution of MW Data used for

Fitting and Testing ASTM D2502 Model

Modeling

Hirschler’s equation

[1], referenced in his paper as (5), defined the “H” function as a modified

version with 0.6 in place of 0.8 used by Bell and Sharp[5].

Ht

= 870Log (Log (Vt + 0.6)) + 154 [1]

where in [1]

Ht = the “H” function

at temperature t

Vt = the kinematic

viscosity in cSt at temperature t

Log = logarithm to

base 10.

The inverse of the of Ht equation [1] is [2] and referenced

as invHt is

Vt

= 10^(10^((Ht -154)/870))-0.6 [2]

For determining the coefficients for the model, equation [2]

converted Hirschler’s data and the chart H100 data to V100. V100 is one of the

inputs for the model.

Equation [3], given by Hirschler as (6), to calculate the

molecular weight of an oil

MW

= 180 + S(H100 + 60) [3]

where

S =

4.146-1.733Log(VSF - 145) [4]

VSF=H100-H210 [5]

and VSF is the viscosity slope factor as defined by Bell and

Sharp5.

Through simple algebraic substitution and rearrangement,

equations [1], [3], [4] and [5], the MW calculation reduces to the form of [6]

MW = [180+4.146(154 + 60)] + [4.146*870]*F1

+ [-1.733*870]*F1*F12

+ [-1.733 (154+60)]*F12 [6]

and generalized to [7]

MW=

C5+C6*F1+C7*F1*F12+C8*F12 [7]

where

F1=Log(Log

(V1+C1)) [8]

F2=Log(Log(V2+C2)) [9]

F12=Log(F1-C3*F2-C4) [10]

C1

to C8 = Coefficients.

Although Hirschler’s paper used log to the base 10, the fit

in GW-BASIC uses Log to the base e. There is no issue in replacing Log base 10 with

log base e (Ln) as they are linearly related by a constant (Log=2.3025*Ln). References

to a Hirschler model in this paper denotes equation [7] using Ln.

Using the initial 110 data points from the chart before the

Hirschler data was available from his paper gave the statistics in Table 6

and the C1 to C8 coefficients in Table 5.

A self-written nonlinear least square (NLLSQ) program written in GW-BASIC[6]

determined the coefficients. After entering a set of initial guesses for the

coefficients, the program used a sequential simplex[7] to

modify the coefficients to find a minimum residual sum of the squares. Eventually,

a set of initial guesses led to a set of “optimized” coefficients, where no other

set of initial guesses seemed to lead to a set of coefficients with a lower

residual sum of squares.

Although, the coefficient set yielded a model with good

regression statistics (Table

5)

the standard deviation for the residuals were higher than desired.

Table 6 Hirschler Model Coefficients

Figure

3 is a plot of the residuals (MW-MWC) from fitting the

coefficients using Lotus[8] 1-2-3

with residual value as data labels. Lines of constant residuals are hand drawn.

The negative values indicate the MWC was higher than the MW from the chart. The

negative residuals delineate a “peak” or area of higher observed values at the

coordinate at MW=400 and H100=400, 600 and a “valley” or area of low observed

values at MW=600 and H100=500 with somewhat elliptical contours. Figure 4 is the same plot as Figure

3 but updated to include all 162 fit data points. It

confirms the original contour plot.

To find an improvement to the fit, higher polynomial terms

for F1, F2 and F12 were added to the initial Hirschler model. All 34 (combinations

with replication) of the first through the fourth order terms and second through

fourth order cross function terms of F1, F2 and F12 (i. e. (F12, (F1)^2, (F1)^4,

(F12)^2*(F1)*(F2), (F12)*(F1)*(F2), (F1)^2*F3^3 etc...) were generated. An

online computational service[9] with

access to a stepwise multiple linear regression program[10] was

used to select the most significant terms for inclusion in the model based on r2

and F-ratio. Equation [11] and the calculation algorithm line (d) shows the

terms chosen and used in the model.

MW=C5+C6*F12+C7*F12*F2^2+C8*F1^4+C9*F1*F2*F12 [11]

This model has a residual

pattern similar to Figure

3 so it was further modified to include corrections for

the high and low residual areas. Since the residual areas appeared elliptic, skewed

and only local deviations needed modeled, a normal distribution was used to

model each area. The modification to the normal distribution included

translation from the origin, rotation of the axis, making it pseudo-bivariate with

elliptic contours and skewing of the distribution. Calculation lines (g)

through (s) and (t) through (af) are these modifications. A more detailed

explanation of the modifications is in the MODEL AND CALCULATION DETAILS below.

The 2 corrections, MW1 (s) and MW2 (af), are added to the initially calculated

molecular weight MW0 along with the bias coefficient C(32) to give the final

molecular weight MWC (ag).

Coefficients

The model fit in GW-BASIC used double precision calculations.

This calculation gave the coefficients 15 significant digits, an amount that

would be tedious to use and masked any calculation sensitivity. The number of significant

digits was reduced for each coefficient until any calculated molecular weights changed

by 0.1. That digit was then added back with rounding to the coefficient. The

sum of the square for the single and double precision sets of coefficients was

867. Table 7

lists the coefficients.

Results

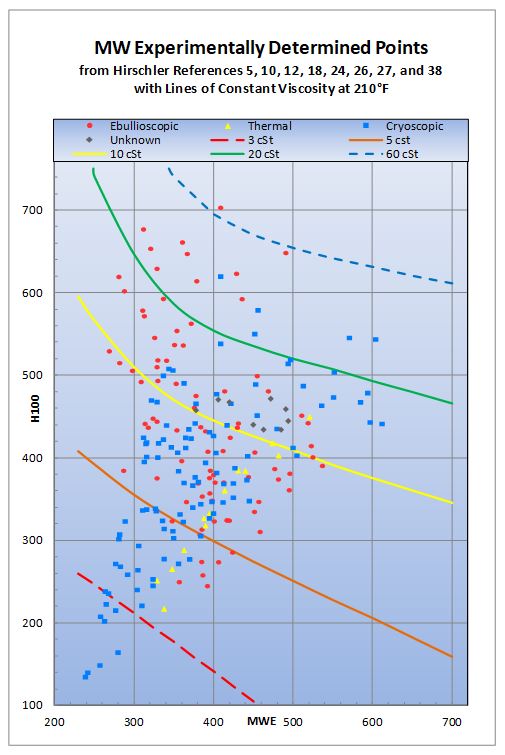

Figure 5

shows the calculated V210 isostokes from the fitted model along with the data

points from the ASTM chart.

Along with Data

Points from ASTM Chart

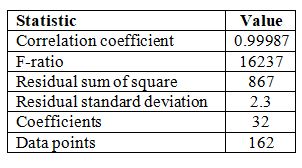

Table 8

is the statistical information or the final fit.

Figure 6,

Figure 7

and Figure 8

are the corresponding line plot, residual distribution and residual normal

probability plot respectively.

Figure 6 Line Plot of ASTM D2502 Model Fit

Figure 7 Residuals from ASTM D2502 Model Fit

Figure 8 Normal Probability Plot of Residuals

from the Model Fit to ASTM D2502

Figure 9

plots the data points labeled with the residual (MW-MWC) from the fit. Points

that have a residual >±4

are highlighted in a white circle. These are clustered on the right edge and

upper right corner. A recent recalculating the results in Excel using the

original data and the reduced precision coefficients verified the model. The Excel VBA code for the calculation is at the

end of the paper.

Figure 9 Final Fit Residuals ASTM D2502

The figures 5 through 9 show how well the model represents

the chart.

There were no distinct patterns in the residuals when

plotted against the independent input viscosities. There did seem to be a

possible “rocket nozzle” like pattern for the residuals versus the MW. The

variation in the residuals was slightly wider at low MW’s and even wider at

higher MW’s. This may suggest a transform of the MW may be useful or it could

be an artifact that the curves drawn by Hirschler are more variable in their

placement because the low and high MW areas have little or no experiment data

to estimate the curve drawing. Additional work later in this paper fitting MW and

MWE to the viscosity data using Table Curve 3D[11]

shows many of the fits used an inverse or Ln transform of the molecular weight.

Figure 10

shows the pattern.

Figure 10 Model Fit Residuals Pattern with MW

Experimental Data

Review

Hirschler’s paper4 examined available data from 9 sources and

chose what he considered the most reliable results and gave that data

“paramount consideration” when designing the chart. These are the reference 26,

27 and 24 with the same major author, same molecular weight determination

method and same oil but somewhat different extraction, distillation and

hydrogenation treatments. This will bias them to be similar but also lends

itself to comparing the molecular weight data with samples of similar viscosities.

The ASTM chart is a modification of a chart in reference 18 page 462. The chart

in this reference has straight isostoke lines and Hirschler considered the

correlation inaccurate. Table 9

lists the references and comments about them. The comments in italics are this

paper’s author. One issue that adds more variability beyond the variability

between the molecular weight methods and viscosity instrument accuracy is the

conversion of SUS[12] to cSt by Hirschler and

this paper’s author. References 9 and 10 has SUS viscosities listed in SUS and

cSt that did not convert using ASTM D2161-93 Reapproved 1992)є2.

There were 233 experimental points. Only 217 are in the area

covered by the chart. Sixteen from reference 12 have H100’s or MWE’s too low to

be put on the chart. Figure

11 shows the distribution of all the experimental data

with labels from Table 9

indicating the Hirschler reference. The point “a” at MWE=172.5 and H100=230.2 is

considered suspect (see Erratum). Figure

12 displays the experimental data covered by the same

area as in the ASTM chart. Data labeled 2, 3 and 4 are from references 26, 27,

and 24 and were the ones given the most weight by Hirschler. It is evident from

Figure 12 that the ASTM chart has sparse experimental data in

the lower and upper right quadrants. There is also limited data below a 250

MWE.

Figure 13

has the experimental points color coded to emphasize the methods used to

determine the molecular weights. Figure 14

is similar for viscosity methods. The color-coding is to show visually any area

that might have a data bias based on methods. The methods are distributed

across the chart.

Figure 13 Experimental Data MW Method

Figure 14 Experimental Data Viscosity Method

The relationship of the 2 viscosities for the experimental

samples is shown in Figure 15

and the distribution of the determined MWE is in Figure 16.

The MWE centers on a 400 MW.

Figure 15 Viscosities of Experimental Samples

Figure 16 Distribution of Molecular Weights

(MWE) for Experimental Samples

The format of the ASTM chart and a plot of the raw

viscosities can mask the high degree of collinearity of the viscosities that is

more evident when the viscosities are plotted as H functions as in Figure 17.

Figure 17 Experimental Samples Viscosities Collinearity

When the axes ranges are limited to the central area in Figure 17,

the MWE labels are less cluttered and more readable (Figure 18).

Figure 18

begins to hint of a molecular weight trend perpendicular to the relationship of

H100 to H210.

Figure 18 Experimental Samples Molecular

Weights

Experimental Best Case (MWE) vs. the Chart (MW)

The purpose of reviewing the experimental data is to

understand how well it compares to the ASTM chart.

Table 10

has 25 experimental points (MWE) selected from the set of 86 points in references

24, 26 and 27. The 86 points are from those given “paramount importance” by

Hirschler. This subset of the total experimental data (214 from 9 references) is

a best-case comparison of the data to the chart. Table 10

also has the corresponding molecular weight data from the chart (MW) and chart

model (MWC) as well as the differences between the various molecular weights.

The comparison of

the chart and calculated MW’s (MW-MWC) has a SD of 3.6. This is higher than the

2.1 in Table 4 found during the fitting of the model to the

chart. The points selected for fitting the model were on the well defined integer

crossing points of the H100 and the V210 line. Only the MW needed

interpolation. For the experimental data, the H100 and viscosity were

non-integer and required estimating where the point was on the chart. The

higher SD of this data reflects this and supports the problem outlined in the

INTRODUCTION.

Table 10

shows, expectedly, that the chart and calculation (MW-MWC) are in better

agreement than the MWE-MW and MWE-MWC differences. The SD for this best case is

better than the SD’s (22, 27) in Table 13,

which is fitting the model to the experimental data. This supports that the

chart is biased toward the data in the first 3 references.

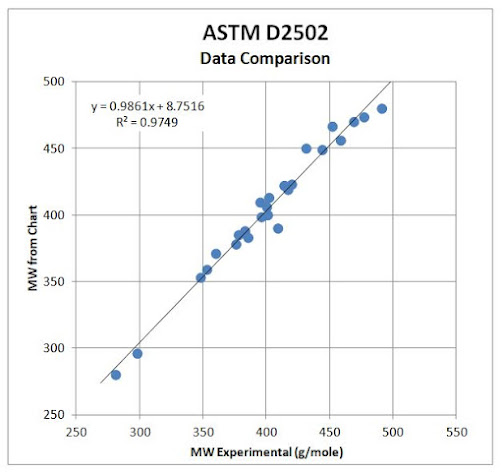

The correlation of the molecular weight data in Table 11

exemplifies that the chart and model are more closely related than they are to

the experimental data. The relationship of the chart and model to the

experimental data is similar. The regression plot in Figure 19 is a plot of the experiment molecular weight and

chart data in Table

10. The regression has a slope of 0.99±0.03 and an intercept of

9±14 and affirms the relationship of the experimental data to the chart. Figure 20 is the pattern of the experimental points for the data in Table 10. Since the pattern covers most of the chart, it is

not biased to any region.

Figure 20 MWE-MW Differences for Data and Chart

in ASTM D2502

Model Predictions

A complete comparison of the difference between the MWE’s

and MWC’s are in the data Table 35

at the end of the paper. The precision of the raw data listed in the table is

that from the references. Graphically the differences are shown as point labels

in Figure 21.

Table

12 compares the molecular weights calculated (MWC) from

the experimental viscosity data using the method in this paper and the

experimentally determined molecular weights (MWE) for each of the Hirschler

references. The model fit has repeatability worse than reading the chart (6 vs.

3). Its reproducibility is much better (6 vs. 25). The model and the chart are

equal in representing the experimental data. A model should not be more precise

than the experimental data. In this case the model is better than the data

because the idealized chart is modeled and not the data. The standard

deviations for the model fit to references 24, 26 and 27 are about one-half to one-third

the other data sources. The experimental data is likely more consistent for

these references as they are by the same main author, on similar oils using the

same molecular weight method and Hirschler gave them more importance in making

the chart.

Table 12 (1 of 2) Details of Molecular Weight Model

Fit to Data from Hirschler,

ASTM D2502 Chart and Experimental Results

Table 12 (2 of 2) Details of Molecular

Weight Model Fit to Data from Hirschler,

ASTM D2502 Chart and Experimental

Results

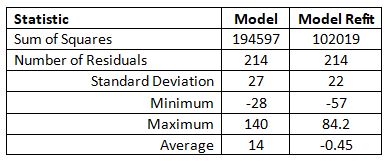

Determining the best coefficients to fit the model to the 214

experimental data points (excluding data in reference 12) showed major shifts

in them that would indicate a much better local or global optimum for the

experimental data was possible. It did reduce the sum of the squares but there

was only a moderate change in the standard deviation of the residuals. Expectedly

with the refit, the minimum residual became more negative and the maximum

became less positive for the refitted model. The average of the residuals

became close to zero as would be expected. Residuals for a good model fit have

a normal distribution centered on zero.

Table 13 Residuals for Fitting Model

Coefficients to Experimental Data

Whether there would be value in attempting to model actual

experimental determined molecular weights to get a better model fit would

depend on the variation of the MWE’s.

Variation of Experimental Molecular Weight (MWE) Data

Using a cluster analysis of the samples’ viscosities to

determine which ones were most similar, gave those listed in Table 15.

Those selected for this list would depend on the clustering method, how to

define the “same” viscosity and the precision of the viscosities and molecular

weight determinations.

There are many forms of cluster analysis. Points visually close

to each other were selected from a chart of H100, MWE and V210 isostokes. These

were compared to a cluster analysis using Euclidean distance measurement with

single linkage amalgamation. The visual proximity of a single pair of points

did not match the cluster amalgamation. The discrepancy seemed related to using

the linearization V100 (H100) versus the non-linear nature of the V210 lines. After

conversion of the viscosity data to F1 and F2 functions that are analogous to

the H100 and H210 function, the cluster analysis gave samples more reasonably

similar for both viscosities. The F1 and F2 functions used were the Ln Ln of

the corresponding viscosity and its corresponding coefficient from the model (as

exampled in calculations (a) and (b)).

The second item

is determining the “same” viscosities. ASTM D445 has a repeatability of 0.0011%

of the sample’s viscosity for base oils at both viscosity temperatures. If the

viscosities fall within the repeatability then they are not considered

different.

The initial

thrust was to find a set of similar samples from the same reference and a set

from different references to get some understanding of the impact of the

analytical methods and reproducibility between laboratories. The data analyzed

consisted of only amalgamated sample pairs. There were no triplicate or higher

amalgamations used. Using the ASTM repeatability gave no set of samples where

both viscosities would be the “same”. To get a minimum of 5 samples preferably

for both sets of samples (same and different references), the repeatability

range was widened. It was not possible to get at least 5 samples for each set.

The closest 10

pairs of samples are in Table 15.

Calculations include values that give the range of molecular weights for the

sample pairs using their maximum and minimum viscosities. The molecular weight with

the maximum V100 and minimum V210 would give the lowest MWC while the minimum

V210 and maximum V100 would give the highest.

Table 14

shows the comparison of the standard deviations (SDs) for selected sample pairs

and that of the MWC. Not included were those having large percent differences

in V100 unless they were from the same reference. Sample pair 5 had a V100

difference of 1.9% yet the molecular weight difference was only 1.0. One would

expect the molecular weight difference to be more if the molecular weight

analysis and correlation of viscosities to molecular weights are reliable. The difference

in standard deviation for sample pairs from different sources, which could also

include different molecular weight methods, compared to the standard deviation for

sample pairs from the same reference was extreme at 22 vs. 1.4.

Table 15 Experimental Samples with Similar

Viscosities

Comparison

ASTM D445 Viscosity Measurements

Viscosity measurements will affect the calculated oil’s

molecular weight. This is not a rigorous attempt at the propagation of error.

The repeatability and reproducibility of the method for base

oils given in ASTM D445 is in Table 16.

Both values are a percent (0.0011 = 0.11%) of the measured value. The measured

value is x in Table 16.

The precision values for base oils are the lowest for the types of oils listed

in the method so represent a best-case scenario.

Table 16 ASTM D445 Percent Repeatability and

Reproducibility for Base Oils

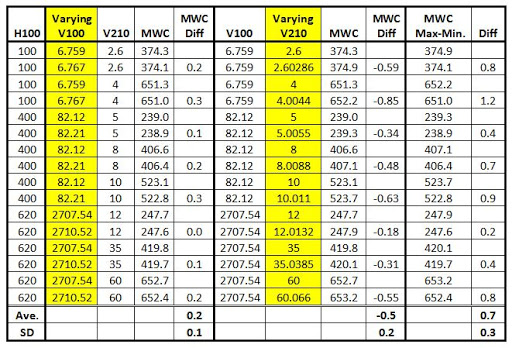

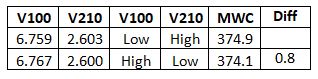

Three H100 values were chosen that represent the bottom,

middle and top of the chart (100, 400 and 620). These represent viscosities of

6.759, 82.18 and 2707.5. Eight V210 viscosities that intersected the V100

viscosities were selected; two for the bottom, three for the middle and three

for the top. Table 17

has the repeatability and Table 18

has the reproducibility. The viscosity values highlighted in yellow are in

pairs with the second in the pair having the repeatability or reproducibility

value added.

For a given V100, a higher V210 viscosity will give a higher

MWC. For a given V210, a higher V100 viscosity will give a lower the MWC. Given

a set of high and low viscosities for both V100 and V210, the maximum MWC for

this set is when the low V100 and high V210 are used. The minimum is when the

high V100 and low V210 are used. Table 19

illustrates this.

The SD for the Max-Min. of the reproducibility is 1.8. As it

is unlikely that both measurements would be at extreme values, the more

reasonable value 1.4 = (0.6^2+1.3^2)^0.5 will be used for comparison. The SD

for the model fit is 2.3 (Table

4).

The variation in the viscosity measurement can approach 60-80% of the model fit.

Table 19 MWC Max-Min. Relation to Viscosities

Maroto and de las Nieves[14]

This paper details a refinement in the molecular weight

calculation by Hirschler where a cubic polynomial of the VSF function replaces the

S function in equation [4].

Doing the various algebraic substitutions led to the

generalized equation for MWC of [12].

MWC=a+bη4+cη3+dη2+eη+fηH+gηH2+hηH3+iη2H+jη2H2+kη3H+lH+mH2+oH3 [12]

where

Table 20 Coefficients of the

Generalized Calculation in the Maroto Paper

The Maroto paper used the H function with the

standard j, k and l coefficients. In this paper, the H functions were a

generalized version at 100oF and 210oF referred to as F1

and F2 where the H function coefficients were optimizable parameters. The S

function has a Log function of the VSF. Using the cubic modification of the VSF

for S, there is no longer a Log function of the VSF. In this paper, keeping the

Log function of the VSF causes the generation of the F12 function, which is a Log

function of the combined F1 and F2. There is no corresponding H12 in the Hirschler-Maroto equations.

A matrix of the 14 terms in equation [12] shows the powers

(order) of the H100 function, the H210 function and the

cross-product terms (X’s).

Table 21 Matrix of Terms in the Hirschler-Maroto Model

Table 22

shows a comparison of the H or F polynomials used in the calculations in this

paper and in the Maroto paper. The 3 tuples in the table indicate the power

of the cross-term functions. The tuple 0,2,1 represents F10*F22*F121.

The Hirschler-Maroto equations have more polynomial terms than the calculation in this

paper. However, the elliptic and skewed normal functions required 22

coefficients (11 for each of the 2 elliptics) for modeling areas of the

residuals but it also resulted in modeling a much wider area of the chart.

What

was interesting about the Maroto paper was how the area of the results

compared to the actual experimental data. Figure 22 has the experimental data shown in Figure 12 bounded by an irregular decagon. The area centered on the H100=590 and

Relative Molecular Mass=380 area are points from Hirschler reference 26 which

he considered “paramount”. In Figure 12, these points have the label 2. The Maroto modification does not model

this area of the ASTM chart.

Figure 22 Hirschler Experiment Data Outlined on

the Restricted Maroto Chart

(Fig. 3. in their paper)

Criticisms

ASTM

This calculation was presented to C. L. Stuckey chairman of

ASTM Committee D02.04 in 1991. At the June meeting, Rinus Daane of Shell

Research, Europe commented that:

1.

The data was a mix of actual and

artificial data, and a correlation of a correlation.

2.

Thirty-two coefficients did not

qualify as a good correlation and was “hocus pocus.”[15]

3.

The viscosities were non-standard

and not at the standard temperatures of 40oC and 100oC.

He recommended leave the method as

is or develop a new correlation.

In response,

1.

The data for the fit was not a mix

of actual and artificial data. Hirschler gave data in his paper to generate the

chart. The calculation used the idealized data from his paper and additional

data points were taken from the chart. All the data was of the same type.

2.

Thirty-two coefficients would

normally be a lot if the calculations were simply using higher order

polynomials that generate small differences to make the fit better. They also

start to model noise. If this was the reason for the polynomials, I would agree

it is “hocus pocus.” However, the polynomials showed significance in the Stat

II fits. Because the polynomials were significant and the coefficients needed

only a limited number of significant digits, I do not believe they represent an

example of Runge's phenomenon[16]

or the modeling of noise.

3. There was no intent for it to be a replacement with new

experimental data or methods but only to model the chart. This work was to

avoid the inconvenience and errors of interpolating data from the chart. The

work showed that about 10% of the molecular weights read from the chart would

be in error. Other ASTM methods have both a chart or table and a calculation

associated with them. By example, ASTM D341 has a calculation with 13

coefficients.

Incorporating the calculation into

the method was due to the lack of a task force leader that could devote the

time needed for the project.

Hydrocarbon Processing

Hydrocarbon Processing rejected the manuscript on

calculation of molecular weight because it did not meet their editorial needs

at that time (12/12/1985).

Concerns

The only concerns are the molecular weight transition for

the EL1 and EL2 elliptic skewed normal distribution sign change. For the EL1,

the transitions are modest being less than 5. The transitions for EL2 are much

larger but are in areas that are on the extreme edge of the chart where there were

no real samples. The section Elliptic

Transition with Skewed Normal Distribution discusses this and is shown in Figure 27 and Figure 29.

MODEL AND CALCULATION DETAILS

Model Background

The purpose of the NLLSQ program was to become familiar with

the modified sequential simplex optimization method and use it to develop

formulation mixtures. It would also provide a flexible least squares fitting program

for use on other laboratory data. It proved inappropriate for mixtures because

of the formulation constraint in that type of design of experiment (DOE[17]).

The misuse of sequential simplex for mixture designs are in the literature[18]. The

fitting of a model to the ASTM D2502 chart was a method to test the program and

possibly avoid the inconvenience of reading the chart.

Hirschler Model F1, F2, F12

F12’ equation [13] is a term used in the Hirschler model equation

[7] before it was generalized. The following steps detail how F12’ was

generalized to F12. It also shows how the functions and coefficient from the

generalization manifested themselves in the higher order function polynomials

of equation [11].

F12’ Generalization

F12'=Log(870*F1-870*F2-145) [13]

Algebraic manipulation of [13] yielded [15].

F12'=Log(870*(F1-1*F2-145/870)) [14]

F12'=Log(870)

+ Log(F1-1*F2-145/870) [15]

The “1” before F2

and the constant 145/870 were generalized by making them C3 and C4 shown in

equation [16].

F12'=Log(870)

+ Log(F1-C3*F2-C4) [16]

The use of F12 simply means the C5 constant in equation [11]

will include the constant Log(870) from equation [16].

F1*F12 Generalization and Reduction

For the C7*F1*F12 term from equation [7], the generalization

of F12’ [16] will generate a second F1 term in equation [18]

C7'*F1*F12=C7'*F1*[F12'-Log(870)] [17]

C7'*F1*F12=C7'*F1*F12'

-C7'*F1*Log(870)] [18]

The C6

coefficient in equation [20] for F1 would essentially be a combination of other

coefficients and constants of the non-generalized form of F12.

C6*F1=

-C7'*Log(870)*F1+C6'*F1 [19]

C6*F1=

(-C7'*Log(870)+C6')*F1 [20]

Model Elliptics + Skewed Normal Distribution Adjustments

The residuals from fitting the Hirschler model have a pattern

of a high “peak” and of a low “valley” area seen in Figure 3. It seemed that the 2 areas could be modeled by 2 modified

normal distributions, a positive and a negated one. They would have a structure

where the value at farther distances from the center of the high or low area

would go to zero and just be adding correction terms to the initially

calculated molecular weight (MW0). The areas also looked possibly elliptic and

possibly skewed on the various sides of an elliptic axes. A calculated elliptic

contour became the basis of a normal distribution creating a bivariate-like

normal distribution from a univariate distribution. Replacing the typical

quadratic power of e with a quartic order polynomial introduced skewing. In

crossing the axes, the X value would become negative. Expecting the sign change

would cause a possible jump in the value from the distribution, the negative X

values were converted to positive values when the axes were crossed. The

calculation used two elliptics, EL1 (m) and EL2 (z).

Elliptics

The axes of the ASTM chart are MW and H100. The translation

and rotation of the elliptics used the axes of MW0 and F2. Since MW is being calculated,

it is not available as data to translate and rotate the axes. Residual contours

of H210 and MW were similar to the contour using H100 but appear more uniform

so the generalized F2 function was used.

Translation and rotation of a function in Cartesian

coordinates from (0, 0) origin to a new origin at (X,Y) are shown in equations

[21] and [22][19].

X = (x − h) cosθ + (y − k) sinθ

= x*cosθ + y*sinθ - h*cosθ - k*sinθ [21]

Y = − (x − h) sinθ + (y − k)

cosθ = y*cosθ - k*cosθ - x*sinθ + h*sinθ [22]

Expansion of

Equations [21] and [22] with the replacement of X with MWS and Y with F2 gives

equations [23] and [24]

X=MWS*CO1+F2*SI1-C(11)*CO1-C(12)*SI1 [23]

Y=F2*CO1-C(12)*CO1-MWS*SI1+C(11)*SI1 [24]

where

X = the translated and rotated

coordinate in terms of MWS (x-axis)

Y = the translated and rotated coordinate

in terms of F2 (y-axis) – note not F1

MWS = the scaled primary molecular

weight MW0 in calculation (e).

SI1 = SIN(C(10))= sine of the

rotation angle of the first ellipse

CO1 = COS(C(10))= cosine of the

rotation angle of the first ellipse

C(10) = angle of rotation (θ) of the

first ellipse determined by regression

C(11) = translation in the x axis (h)

determined by regression

C(12) = translation in the y axis (k)

determined by regression

Figure 23 Translation of the Origin and

Rotation of Axis with Elliptical Contour

Equation [25] shows the standard elliptical.

X2/b2+Y2/a2=1 [25]

Since equations [23] and

[24] have the translation and rotation incorporated, there was no need to do

the translation to the center point of the ellipse or its rotation. The new

origin coordinates (X, Y at point OT) were divided by regression determinable

coefficients C(13) and C(14) making them equivalent to equations [26] and [27].

X/b=X/(C(13) [26]

Y/a=Y/(C(14) [27]

Combining [23] with [26] and

[24] with [27] gives the form of the calculations for the elliptics.

Calculations (i) and (k) shows these the elliptic contour forms EL1 (v) and EL2

(x).

X1 and Y1 were then squared

(calculations (j) X12 and (l) Y12) and added together (calculation (m)

EL1=X12+Y12) to make an elliptic contour defined as EL1. EL2 used the same

calculations but with other coefficients.

A normal distribution used

the elliptic contour values to calculate the adjustment in the initially calculated

molecular weight (MW0). Equation [33] shows a generalized normal distribution

(GND). The modified generalized normal distribution (MGND) equation [35] was

the GND altered by having Euler’s e raised to the 4th power

of the elliptic contours EX1 or EX2. An issue might occur if the distribution did

not have a smooth transition across the elliptic axis and result in jumps in

values when the point was on one side of the axis or because of the odd terms

in the distribution. Changing the signs of the elliptic values on opposite

sides of the axes made them consistent. Using them in the higher order polynomial

normal distribution, the coefficients would regress to the appropriate negative

or positive values. If the calculation in equation (n) indicated the EL1

(ellipse 1) in equation (m) was negative, it was made positive by multiplying

by -1 in equation (p) (EX1, exponent 1).

In the calculation, the

coordinates of the center of the ellipse was defined by the coefficients

(C(11), C((12)) and the point P1 by the coordinates (MWS,F2). To determine

which side of the rotated and translated ellipse a point was on, the coordinates

of the point would be used to calculate the angle of the point from the original

axes. Figure 24

visualizes putting the center or origin of the ellipse, point OT (origin

translated) in Figure 23,

superimposed on the original origin. Angle ϕ of the point would be compared to

θ, the angle of the rotation of the ellipse (C(10) for ellipse 1). If ϕ> θ

or (Tanϕ>Tanθ), it would be considered on one side of the axis. Otherwise,

its sign is changed. Tanϕ is the length of H/length of D. In terms of the

coordinates of the 2 points (P1 and O) and the coefficients in the model, equation

[28] defines Tanϕ.

Tanϕ=(F2-C(12))/(MWS-C(11)) [28]

We are looking

for

Tanϕ>Tanθ [29]

Substituting in

equation [28] and the tan of the axis rotation, Tan(C(10))

(F2-C(12))/(MWS-C(11))>Tan(C(10)) [30]

0>Tan(C(10))*(MWS-C(11))+C(12)

-F2 [31]

gives equation [31] which is

the form of calculation (n) and (aa) to SG1 and SG2. The algebraic manipulation

rules for the multiplication or division of an inequality were not necessary, as

the absolute value of the sign is not important. For the calculation, it is

only important to know if they are on the same side of the axis and if they are

not then the sign is made the same. Figure

25 uses the tangent calculation equation to determine

the sign on either side of an ellipse axis. The x and y values are

representative data. The labels on the axes and title are the actual data name

or calculated intermediate used in making the model but are appended with an

apostrophe (’) to indicate the use of representative data in making the figure.

Skewed Normal Distribution

Starting with a normal distribution equation [32],

generalizing to give the generalized normal distribution (GND) [33] by

consolidating constants and expanding the exponential term, and then replacing

the exponential term with a higher order polynomial [34] gave a modified

generalized normal distribution (MGND) equation [35]. Recent literature has

referred to this as a flexible skew-symmetric distribution[20], [21], [22], [23].

GND=ae-(b+cX+dX^2) [33]

(b+cX+dX2+eX3+fX4) [34]

MGND=ae-(b+cX+dX^2+eX^3+fX^4) [35]

X in equation [35] represents EX1 in calculation (p) and EX2

in calculation (ac). The polynomial [34] is written in the Horner[24] nested

polynomial format to avoid generating large numbers with the higher

polynomials. It was also broken into parts for easier coding and represented by

calculation (q), (r), and part of (s) and calculations (ad), (ae) and part of (af)

for the 2 elliptic skewed normal distribution adjustments. Calculations (s) and

(af) yield the elliptic skewed normal distribution adjustments to the molecular

weight. Equation 36 represents the full function calculation of adjustment 1

with the coefficients being represented without the array parenthesis.

MW1=C15e^(-(C16+C17*EX1+C18*EX12+C19*EX13+C20*EX14) [36]

Figure 26

shows some of the various forms that can be generated by higher order

polynomials in a normal distribution and Table 23

has some description details with the coefficients used to generate the curves.

Figure 26 Examples of Higher Order Normal

Distributions

and the Coefficients of the Powers of X

The “a” through “f” coefficients in Table 23

are those in equation [35]. EX1 and EX2 are the ellipses from the fit. They

were both negative. A rescaling of EX1 and EX2 allowed plotting them in Figure 26.

EX1 has a small minimum so rescaled larger. EX2 was massively larger and

rescaled considerably smaller to fit on the chart. There is a considerable

range of forms for the residuals that adjusting these terms could model.

A second skewed normal distribution calculated (calculations

(aa) through (af)) in the same manner as done for the first. This generated a

second molecular weight adjustment (MW2)

The base molecular weight MW0, MW1 from the first elliptic

and skewed normal distribution and MW2 from the second elliptic and skewed

normal distribution are combined to get the final calculated molecular weight

(MWC).

Elliptic Transition with Skewed Normal Distribution

One of the

concerns was how well this would work. No transition issues were apparent when

originally investigated. In preparing the graphic visualization of the

transition lines with more granular inputs, they appeared.

Figure 27 to Figure 30 shows the sign transition for both ellipses. The

first chart of each pair uses the same axes (H100, MW) as the ASTM chart while

the second has axes based on the calculation parameter used for the ellipses

(F2, MW0). The use of F2 causes the curved transition lines in Figure 27, Figure

29 and Figure 33.

All the figures show smooth transitions but the granularity is the size of the data

point on the plot.

Figure 27 Ellipse 1 Sign Transition

Figure 28 Ellipse 1 Sign Transition

Figure 29 Ellipse 2 Sign Transition

A granularity of

<0.05 for the H100 function showed the transition.

Figure 31 and Figure

32 show the magnitude of the effect for EL1 and EL2. Table 24

lists the values for EL1 and EL2 at various V210’s. For EL1 the maximum amount

is 5 at a V210 of 6 and for EL2 is a maximum of 15 at a V210 of 60. Figure 33

shows the transition for the experimental data. The EL2 transitions are

essential in an area devoid of any experimental data and would have a low

likelihood of being encountered in practice (Figure 33).

The EL1 transition is in an area where there is experimental data close to the

middle of the data. Although the amount is higher than desired to match the repeatability

of reading the ASTM chart, it is within the reproducibility and similar to the

difference seen with experimental samples.

Figure 33 Elliptic Transitions with

Experimental Data

Coefficients Purposes

The coefficients are color-coded indicating their use in the

calculation.

Table 25 Coefficients Color-Coded by

Function in the Calculation

Table 26

Explanation of Model Coefficients

Viscosity Conversion

Some of the viscosity data in the references is SUS. For use

in the calculation, they had to be converted to cSt. The calculation {1} of the

SUS from cSt at a temperature T used the formula given in ASTM D2161-93

(Reapproved 1992)є2 page 2 Equation (6). This equation was used to

convert SUS data reported in the references to cSt for input to the model.

SUS

is calculation is cell A1

=

(1+0.000061*(C1-100))*(4.6324*B1+(1+0.03264*B1)/((3930.2+262.7*B1+23.97*B1^2+1.646*B1^3)*0.00001)) {1}

where

the cell references in {1} are defined in Table 27.

Table 27 Cell Content for Calculation SUS from

cSt

Some references with viscosity and molecular weight data reported

both SUS and cSt viscosity values. Using {1} did not give the same cSt

reported. A reverse calculation from cSt to SUS was used to further compare the

2 reported viscosities. Previously a method for doing the reverse (InvSUS) calculation

had been developed. It is detailed in the Calculation Codes section. Since it

was available, the cSts reported were converted to SUS and reaffirmed the

values did not convert equivalently using the current calculation. This adds

another element of variability in the experimental data as all of the

references that used SUS and converted for use by Hirschler or the reference’s

authors may not be consistent with the current conversion method.

REVELATIONS

Experimental Data MW Trends

The MWE data follows trends. It increases from samples that

have low values of H100 and H210 to those that have high values as shown in Figure 34.

This is not a surprising trend, as higher molecular oils would generally have

higher viscosities and give higher H functions for both. In Figure 34,

the MWE’s have only their first digit plotted to make the chart readable. The

MWE’s vary from 250 to 450 along the dotted regression line of H100 and H210.

Figure 34 Experiment Molecular Weight Trend

Related to H Functions

Figure 35 Variation of the Average Molecular

Weight along the Regression Line

In addition to this trend, a trend of decreasing molecular

weights perpendicular to the H100 and H210 regression line is discernible in Figure 34.

Figure 36

using MWE/100 data labels and Figure 37

using data points show the data and trend more clearly. The reason for choosing

lines perpendicular to the H100 and H210 regression line was arbitrary based on

the appearance of the molecular weights on either side of the trend line. Figure 36

and Figure 37

have points chosen close to several perpendicular lines by calculating the

distance from the experiment points to a specific perpendicular line and

selecting a subset of the closest ones.

Figure 36 Experiment Molecular Weight Trends

Perpendicular to the

H100 and H210 Regression Line

Figure 37 MWE Data Point Proximity to

Perpendicular Lines

Other Approaches

The near linear components of the 2 trends in Figure 34

and Figure 37

suggested that other approaches may have interest for both fitting the data to

the ASTM chart (MW) and to MWE. These would include:

1. Principal

Component Analysis (PCA)

2. Fitting

a function to the H100 and H210 relationship and then fitting a function

perpendicular to that trend

3. Do

the same as described in 2. but in the reverse order

4. Multiple

Linear Regression (MLR)

5. Fitting

the data with a 3D fitting program like Table Curve 3 D.

PCA selects perpendicular principle components although

there might be some variant that fits non-perpendicular components. This was

the reason for suggestions 2. and 3. as they could include a parameter to vary

the angle off the perpendicular of the lines crossing the molecular weight

trend of the H100 and H210 regression line. Some of these approaches may be

degenerate and lead to essentially similar types of fits.

MLR and Table Curve 3D

The data H100 as x, H210 as y and either MW or MWE as z was

fit to equations using Statistica and Table Curve 3D. These programs report the

standard deviation of the fit as the standard error of estimate.

The equation fits of MWE in Table 30

named MLR 1 from Statistica and Best 3 from TC3D had standard deviations (23,

26) similar to the standard deviation of nearly replicate experimental data given

in Table 14

(22) indicating that there are unlikely to be any models that will fit the

actual experimental data better. Figure 38

is a plot of the TC3D fit Simple 4 and Figure 39

is a plot of the residuals for the Simple 4 fit. They give a visual

representation showing how difficult it would be to find a better model due to

the points being about equally above and the surface of the fitted plane and

being nearly uniformly scattered across it. One of the data points that is

considered a possible outlier is clearly evident in Figure 38

as a red dot with a long red line to the equation plane. The residuals plot in Figure 39

shows a second possible suspected outlier. The circles represent the data

points with the fill colors representing the size of standard deviation. The

color of the lines from the point to the fit plane and the point border color indicates

whether it is above or below the plane. Table 28

is a description of the color-coding used in Figures 38 to 40.

For the Statistica data, the standard deviation of fits to

MWE and MW appear odd in that the standard deviation for the MW is greater than

for the experimental data. The MW data covers a wider area and is not as linear

as the MWE data making the error in a simple linear fit to the chart data greater.

For the best TC3D fits (Best 3 of MWE and Best 6 of MW),

there is a significant reduction in the standard deviation fit for the MW data.

A feature of the Chebyshev[26] polynomial

is it generates a smooth and continuous curve. The bivariate form makes a

surface. Figure 40

plots Best 6 for the MW data as a visual representation that the data points lay

on the smooth continuous equation plane. Because of the smooth and continuous

fit, a better fit to the MW data is unlikely. The same is true for the

Chebyshev fit to MWE. As typically seen with extrapolated empirical fits, areas

outside the fit may not realistically represent data in those areas. The

Chebyshev fit has a “wall” plane on the right of Figure 40

that would not represent any experimental data in that area. The standard

deviation (1.7) for the fit Best 6 was very close to the standard deviation for

the fit model in this paper (2.3 Table 8).

The “Best” equations and the “Simple” equations are considered limiting cases

showing the range of standard deviations for the 2 sets of data.

The Chebyshev Bivariate Polynomial Order 10 is more complex to implement, has 66 coefficients and each coefficient will need at least 6 significant digits (precision) for calculations. Table Curve does not appear to check each coefficient for needed precision but reduces all of them equally starting at 18. The coefficient precision data in Table 29 shows that 6 digits will give a maximum error less than the ASTM repeatability error (Table 4). Coefficients with the next lower precision (5) are significantly worse.

Table Curve 3D has the ability to generate code for the

fitted equations. The inputs for the code are the H100 and H210 values of V100

and V210. Code is available for C 64 bit, C 80 bit, Pascal, Basic, Fortran 77,

Fortran 90, Java, Matlab and C++ from the author.

The Chebyshev

Bivariate 10th Order Polynomial C++ code is at the end of the

paper.

Table 30 Table Curve 3D Equation Fits to MW

and MWE

Figure 38 TC3D Equation Simple 4

Ln(MWE)=a + b*H100*Ln(H100)+c*(H210)

Figure 39 TC3D Equation Simple 4 Residuals

Ln(MWE)=a + b*H100*Ln(H100)+c*(H210)

Another interesting aspect of the TC3D fits was that for

many of the better fits there were data transforms applied. In particular, H100

had an additional logarithmic transform essential making that data a triple

logarithmic transform. The MW and MWE had many fits with an inverse or logarithmic

transform.

H100-H210 Relationships

The parameters added to the F1 and F2 functions used in this

paper instead of using H100 and H210 would give additional flexibility for

attempting to fit a model. Varying the relationship between F1 and F2 in function

F12 would give even more flexibility.

The parameter added to the viscosity is limited to those

that are greater than one minus the minimum viscosity in the data set

(>1-Min(Vt)). This is because the inner Log has to give a value

>1 otherwise the outer Log would be the Log of 0 or a negative number and

undefined. The other constraint is if the viscosity + the parameter become very

small and close to the minimum viscosity, the F function will become extremely

negative.

Below are some figures with MWEs that have various constants

added to the viscosities. They exclude the low viscosity data from Reference 12

most of which would not be on the chart. The minimum V100 and V210 is 5.5052

and 1.78 respectively. Note that experimental point number 123 with the V210 of

1.78 in reference 9 is not on the chart but has no impact on the concept being

exampled. The parameters have to be greater than -4.5052 and -0.78. The figures

list the F1 and F2 parameters used to generate the charts in the title in the

order for F1, F2. The red point in the figures is a suspect data point that was

> 3 standard deviations for the fits.

Table 31

is a grid of figures. Figure 41

has the H functions as a reference and Figure 42,

Figure 43

and Figure 44

have parameters near the low viscosities for the both the F1 and F2 function.

Inspection of Figure 42

shows that the data point, which has low viscosities for both temperatures, is

at an extreme distance from the other data point and would cause it to have a

very high leverage, if used in any fitting. Similarly, both Figure 43

and Figure 44

have a point that is errant or extreme. This would cause issues in fitting

models.

Table 32

is a grid of the F function parameters to show the different relationships between

V100 and V210. Figure 45

with small F1 and F2 parameters (0, 0) not close to the minimum viscosities is

essentially the same as Figure 41

but with different axis scaling. The others take various forms and have

descriptive names. The more interesting one is Figure 47,

the “Fan”. It is interesting because it expands the relationship giving greater

variation in the correlation between the viscosities. This is somewhat similar to

the belief in PCA that finding a principle component will increase the spread

for the next principle component and help in making a model. It also reduces

the collinearity. The others might be useful if a more complex function of the

relationship of F1 to F1 is used for modeling.

Table 32 Grid of Low, Medium and Large F

Function Parameters

CONCLUSIONS

The calculation models the full range of the ASTM D2502

chart better than any other previously known method. Any differences between

the chart and the model do not have any practical significance as the calculated

molecular weight matches the chart better than the chart matches the

experimental values as shown in Table 11

correlations. Viscosity measurement errors are 60-80% of the fit. The

convenience of use, the reduction of interpolation and reading errors, results

better than the reproducibility of the method, results similar to the

repeatability and similar to the measurement errors make the use of the

calculation viable.

The Chebyshev X,Y Bivariate Polynomial Order 10 model was

found and can be considered for use in modeling the chart. It would not have

the sign change transitions as the model in this paper. It offers a modest but

likely not significant improvement in the standard deviation of the residuals

(1.7 vs. 2.3). It is more complex to implement, has 66 coefficients and each

coefficient will need at least 6 significant digits for calculations to give

less than an absolute maximum error 0.4 MW.

It is unlikely that a better model to fit the experimental

data is possible based on the standard deviations of the experimental data and

that models of the current experimental data give nearly the same standard

deviations as the data.

FUTURE

Functions that actually model the peaks and valleys as

originally seen in Figure

3 and Figure 4

and avoids the molecular weight transition caused by the sign change across the

elliptics would be of interest. Some possible refinements mentioned in the

REVELATION section. The elliptic skew normal distribution replaced with the

bivariate flexible skewed normal distributions detailed in the references (20,

21, 22 and 23) would likely avoid the transitions. The refinements are unlikely

to have any practical significance that would merit any significant additional

work.

Determining the standard error of the coefficients might

make it possible to reduce the number of coefficients and allow refitting of

the model to make it simpler.

To get a model that is closer to the experimental data would

require a significant amount of work to generate new consistent data. The data would

likely show that additional independent factors beyond the 2 viscosities may

then be needed. Getting a model that is causal and theoretically based would be

the best goal.

DATA: INPUT and OUTPUT

Model Fitting Data

Table 33

below is the raw data used to generate the coefficients for the model. The V100

Input is calculated from H100 using equation [1]. The source of the data was

Hirschler[27] (H) or Chart (C). HC denotes

duplicate data given by Hirschler and taken from the chart. Only the Hirschler

values were used for the model fit. The duplicate data differed only in the

H100 value list in the Not Used column. The Hirschler values for H100 were

integers in his paper. The H100 values from the chart had to be estimated from

the MW lines and V210 isostokes. This highlights the difficulties in estimating

values and the introduction of errors that can occur.

Model Validation Data

The data for testing (validating) the model was randomly

generated pairs of values for V100 and V210. Any pairs not on the chart were

discarded. The H100 values were calculated and used with the V210 to estimate

the MW from the chart.

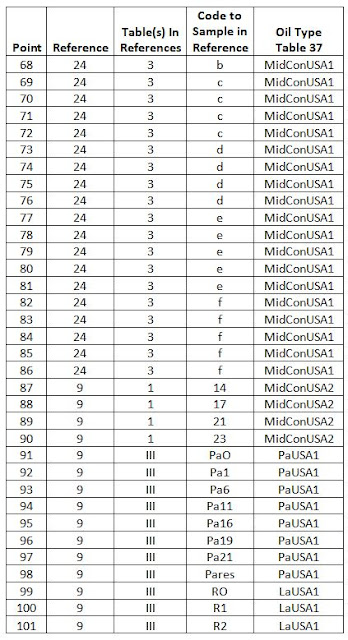

Experimental Data

Table 35

is the experimental data used by Hirschler to generate the ASTM D2502 chart.

The Chart Label column uses single characters for some figures to make them

more readable.

Table 36 contains tracking data for referencing back

to the original sources and the types of oils used to generate the data.

Calculation Codes

GW-BASIC

The code listing has inputs of the 2 viscosities and outputs

the calculated molecular weight.

There were some issues with using various forms of BASIC.

Some require line numbers and a termination line at the end of the listing;

others do not. In hexadecimal, the line termination line was 1A 20 0D 0A and in

decimal 26 32 13 10. These represent ASCII characters for SUB SPACE CR LF

(substitute[28], space, carriage return, line

feed). CR and LF are commonly used to terminal ASCII text files.

GW-BASIC Code listing:

10

Rem for V1 and V2 of 145 and 10

20

Rem the MWC is 398.3604

30

DEFINT K

40

DIM C(32)

50

C(1) = 4.11

60

C(2) = 1.358

70

C(3) = 1.5414

80

C(4) = -0.4106

90

C(5) = 197.6

100

C(6) = -592.944

110

C(7) = -96.08

120

C(8) = 0.8759

130

C(9) = 154.29

140

C(10) = -1.513

150

C(11) = 4.126

160

C(12) = 2.356

170

C(13) = 1.07

180

C(14) = 1.446

190

C(15) = -31.5

200

C(16) = -0.64

210

C(17) = 0.069

220

C(18) = 0.31

230

C(19) = -0.032

240

C(20) = 0.002

250

C(21) = -1.267

260

C(22) = 8.05

270

C(23) = -4.326

280

C(24) = 6.223

290

C(25) = 300

300

C(26) = -0.00326

310

C(27) = 19.54

320

C(28) = -30.387

330

C(29) = -12.02

340

C(30) = 7.276

350

C(31) = 6.498

360

C(32) = 52.3

370

INPUT "Enter Viscosity at 100F in cSt: ",V1

380

INPUT "Enter Viscosity at 210F in cSt: ",V2

390

F1=LOG(LOG(V1+C(1)))

400

F2=LOG(LOG(V2+C(2)))

410

F12=LOG(F1-C(3)*F2-C(4))

420

MW0=C(5)+C(6)*F12+C(7)*F12*F2^2+C(8)*F1^4+C(9)*F1*F2*F12

430

MWS=MW0*.01

440

FOR K=0 TO 1

450

K11=K*11

460

SI=SIN(C(10+K11))

470

CO=COS(C(10+K11))

480

X=(MWS*CO+F2*SI-C(11+K11)*CO-C(12+K11)*SI)/C(13+K11)

490

X2=X*X

500

Y=(F2*CO-C(12+K11)*CO-MWS*SI+C(11+K11)*SI)/C(14+K11)

510

Y2=Y*Y

520

EL=X2+Y2

530

SG=TAN(C(10+K11))*(-C(11+K11)+MWS)+C(12+K11)-F2

540

IF SC<0 THEN SG=-1 ELSE SG=1

550

EX=SG*EL

560

EX1=EX*(C(19+K11)+EX*C(20+K11))

570

EX2=EX*(C(17+K11)+EX*(C(18+K11)+EX1))

580

MW2=C(15+K11)*EXP(-(C(16+K11)+EX2))

590

IF K=0 THEN MW1=MW2

600

NEXT K

610

MWC=MW0+MW1+MW2+C(32)

620

PRINT USING "MWC= ####.####"; MWC

Excel VBA Functions

Molecular Weight Calculation Functions

There are 4 functions used to calculate the molecular weight

from viscosities at temperatures more common today than when the chart was

developed. The code for the functions is at the end

of this section.

1. MW40_100

is the top level function. Viscosities in cSt at 40°C, 100°C and the type of

viscosity

boundary error checking are the inputs. The function is hard coded to convert

viscosities from 40°C and 100°C to 37.778°C and 98.889°C (100°F and 210°F). It uses

the viscosity-temperature conversion function VisAtTC (Viscosity at Temperature

C)

and passes the converted viscosities to the MW function.

2.

VisAtTC converts the viscosities from two

temperatures to the viscosity at a 3rd

temperature. It is usable as

a standalone function as long as the required Log10 function

in VBA is

available.

3.

The Log10 function converts the native

VBA Log (base e) function to base 10[29]. As

a

standalone function, it is usable as needed in VBA. It is not for use in

spreadsheet cells as

the spreadsheet has both the Log and Ln as native

functions.

4.

The MW function calculates the molecular

weight using viscosities at 100°F and 210°F,

checks the viscosities for chart boundary

violations and returns the MW or boundary

violation code. It is usable as a

standalone function if V100 and V210 are the inputs.

MW Calculation from Viscosities at 40°C and 100°C

The function is MW40_100(V40C,V100C, optional Error Report

Code).

The molecular weight data used to check the viscosity

boundary violations was used to check the conversion of the viscosities from

100°F and 210°F to 40°C and 100°C and their use in this function. For all

values that are on the chart, the difference between the originally calculated

MWC and that from the viscosity converted MW40_100 version had a difference of <0.15.

Any values that showed larger differences had viscosities that would not be on

the chart, a V210 that was difficult to interpolate below 2.6 cSt (lower left

corner highlighted in yellow) or above 60 cSt. All the viscosity boundary

violations had the same error code except the point in the lower left corner of

the chart.

Table 38 Viscosities Converted to 40°C

and 100°C, Checked Against Previous Calculations

Conversion of Viscosity from 40°C and 100°C to 100°F and 210°F

The function is VisAtTC(p1, p2, p3, p4, p5). The parameter p1

represents the viscosity in cSt at the lower temperature p2 in Celsius. Parameters

p3 is the viscosity at the higher temperature p4. The parameter p5 is the

temperature in Celsius at which the viscosity is wanted.

The viscosity conversion uses the Wright equation[30],

which is the basis[31]

for ASTM D341[32].

Four sets of data were used to check VisAtTC (Viscosity at

Temperature C) function code against online calculations and gave comparable

results. Five other data sets were used to check its viscosity range (Table 39).

The differences seen on the low viscosities are irrelevant as they would not be

on the ASTM chart.

Table 39 Preliminary Testing of

Viscosity-Temperature Conversion Code

This function requires the use of the log (base 10) function,

which is not native to VBA. Included in the code list is the function Log10,

which converts the VBA natural Log (base e)

to the log base 10.

MW Calculation from Viscosities at 100°F and 210°F with Boundary Violation Discussion

The code is a VBA function MW(number1, number2, optional

text) that calculates the molecular weight using the method described in this

paper. It includes validating that both viscosities are within the chart area. The

inputs number1 and number2 are numbers or cell references to the viscosities

with number1 as the viscosity in cSt at 100°F and number2 as the viscosity in

cSt at 210°F. The optional text is either a text string in quotes or a cell

reference to text content. The optional text controls the type of error message

reported by the function.

The output is the calculated molecular weight or an error

code. The error codes will help determine which viscosities or which chart

boundaries are violated. The code terminology relates to the ASTM chart, as

that is more familiar than the modified charts (Figure 51

and Figure 52)

based on viscosity axes.

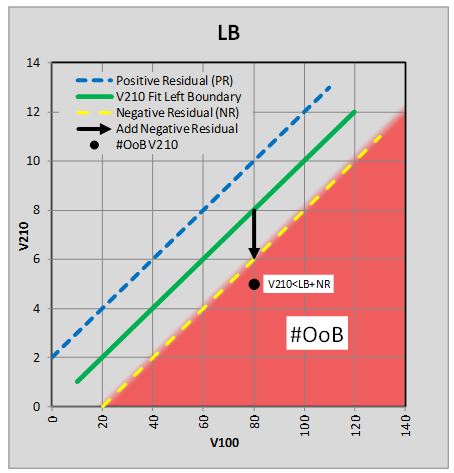

Boundary Violation Details

The ASTM D2502 chart has a distinct form (Figure 50).

Figure 50

shows the vertex points and boundary lines. The legend refers to those

boundaries on the chart. Table 42

has the color-coding for the boundaries with descriptions and limits.

Table 42 Boundary Descriptions

The chart area below a V210 of 2.6 was not considered for

determining boundary limits because of the difficulty in determining the V210

at the point MW=220 and H100=100. The MWC estimates a viscosity of 1.927 cSt,

while estimating the point from the chart was between 1.725 (linear) and 1.95

(non-linear). Using the MWC value to fit the left boundary limit equation gave

a very high residual. If the higher residual for the corner point is used, the left

boundary constraint equation values would not flag V210 values that are well

off the chart and would be ineffective as a warning for invalid V210s.

A modified version of the chart (Figure 51)

used the viscosities for the axes. The legend and color-coding of the boundary

lines is consistent between the 2 charts. Some of the bottom boundaries are

difficult to discern and are visually clearer in Figure 52,

which is the same as Figure 51

but with both scales logarithmic. This helps with deciding how to set up the

boundary conditions.

Figure 50 Vertices and Boundary Lines on the

ASTM D2502 Chart

Figure 51 Fitting Data and Boundary Lines with

Viscosities as Axis

Equations were determined for both the right and left edges

(boundaries) of the ASTM chart. Table Curve 2D[35] fitted

V2 as a function of V1. The criterion for the function was the smallest standard

error that was consistent with a function that was rational, smoothly

increasing over the V1 range and computational straightforward to implement.

Consideration was not given to whether single or double precision was required.

There is no data for the left boundary of the chart from

previous work. An expanded digital picture was used to estimate the values for

the fit. Table 43

has the raw data values read or estimated from the ASTM chart, the input and

output for TC2D and a comparison of the chart MW with the MWC. The MWC compares

favorably to the chart MW with a standard deviation of 2.4 for the

difference between the chart MW and MWC. This is consistent with the standard

deviation for the chart fit in Table 4.

Table 43 Chart Points for Fitting Left Edge

Boundary Equation TC2D

Figure 52

is the left boundary calculation for V2 in terms of V1 from Table Curve 2D. The

function begins to become bimodal after the maximum V1. In Excel, the VBA MW

calculation function will never check for a V1> than the maximum for the

boundary, so the second value for V2 will not be encountered and cause the V2

value to be misreported as being on the chart when it is not.

Figure 53 Table Curve 2D Equation

Fitted to Left Edge of Chart

The boundary limit function and coefficients for the left

boundary are in Table 44.

The coefficients were initially single precision but it introduced some minor

differences in the calculated boundary values. Using double precision

eliminated the differences.

Table 44 Equation and Coefficient for Left

Boundary Limit of V210

The residuals in the calculated V210 were similar in scale

so an absolute value was used to adjust the boundary limit calculation. The

boundary limit calculated was adjusted by adding a value (-0.040) slightly less

than the largest negative fit residual for the data (-0.036 Table 43

point 21) and testing if V210 was < the adjusted limit. This assures that

none of the chart limit points would be incorrectly reported as out of bounds

due to residual fit errors. Figure 54

is a stylized graph with example values showing the methodology. At first

glance, the stylized graph may seem peculiar but it has to be referenced back to

Figure 51

with viscosity data, where the lower V100 boundary represents the left ASTM

chart boundary and the V210 data above the green line is V210 values on the

ASTM chart.

Figure 54 Stylized Chart Showing Adjustment to

the Left Boundary Limit

A similar procedure was done for the RB. The data is in Table 45.

There was some previous data on the RB and this was augmented with additional

points highlighted in yellow.

Figure 55 Table Curve 2D Equation

Fitted to Right Edge of Chart

The boundary limit function and coefficients for the right

boundary are in Table 46.

For the right boundary limit the methodology was similar but

the maximum residual was added and the test for OoB was V210 > the adjusted